-

pp single secrew extruder melt blown mask machine production line

The production line of melt blown pp extruder non-woven fabric is stable in operation, high in production and high in efficiency. The produced non-woven fabric has uniform net laying, good strength, good air permeability, non-toxic and tasteless, and meets ...

-

Single s spunbond non woven cloth extrusion production line

Edge screw and recovery device ----- > screw melt blown extruder ----- > filter ----- > metering pump ----- > monomer suction device ----- > spinning box ----- > cooling air box ----- > drawing device ----- > mesh forming machine

-

Double s spunbond nonwovens production line

Process flow chart of double s spunbond nonwovens production line Additives (scrap recovery) ---- raw materials - > melt extrusion - > filtration - > metering - > spinning - > cooling - > drawing - > Netting - > hot rolling - > winding - > slitting - > finished products

Introduction of melt blown cloth extruder machine

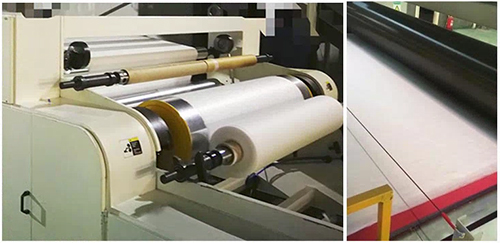

The production line of melt blown non-woven fabric is stable in operation, high in production and high in efficiency. The produced non-woven fabric has uniform net laying, good strength, good air permeability, non-toxic and tasteless, and meets the environmental protection standards. It is applied to non-woven fabric for clothing, medical and health materials, construction, industry, agriculture, hotel disposable products and other non-woven and industrial fabrics.

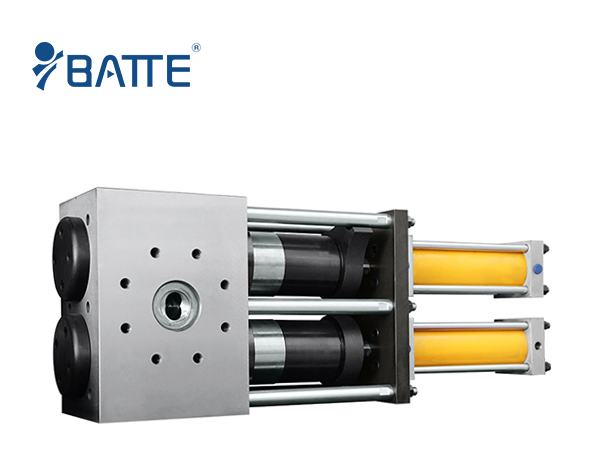

Equipment display of melt blown non-woven fabric production line

Raw material: PP polypropylene

Melt index of spunbond PP: 28-45

Melt blown PP melt index: 1300-1800

Melting point: 166 ℃

Denier number of spunbond fiber: 1.8-2.5 denier

Melt blown fiber denier: 1.6-4 μ M

Components of melt blown non-woven fabric production line

Edge screw and recovery device ----- > screw extruder ----- > filter(screen changer) ----- > metering pump ----- > monomer suction device ----- > spinning box ----- > cooling air box ----- > drawing device ----- > mesh forming machine ----- > hot rolling machine ----- > coiler ----- > Slitter

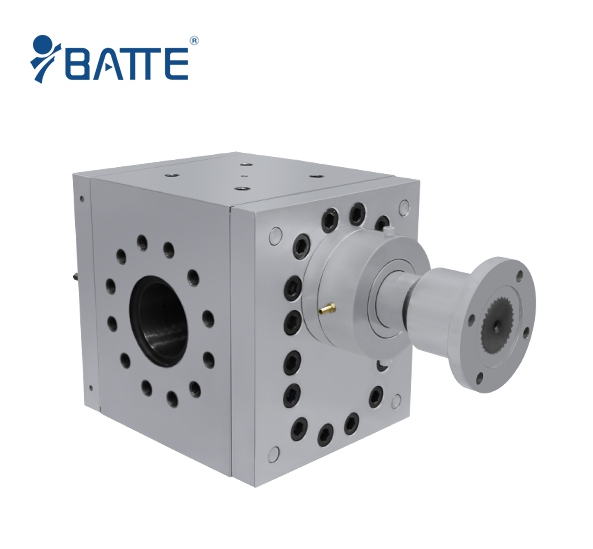

The model and configuration of pp melt blown extruder melt metering pump and filter in the melt blown cloth production line are as follows:

| Standard configuration of metering pump and filter (screen changer) in melt blown cloth production line | ||||

| Screw specifications | Output |

Width of melt blown cloth | Model of metering pump |

Model of filter (screen changer) |

| Φ45 | 10-20kg/h | 600mm | ZB-M-10CC | ZB-2MR-100 |

| Φ65 | 20-60kg/h | 1200mm | ZB-M-20CC | ZB-2MR-120 |

| Φ90 | 60-100kg/h | 1600mm | ZB-M-30CC | ZB-2MR-150 |

| Φ105 | 80-150kg/h | 2400mm | ZB-M-50CC | ZB-2MR-175 |

| Φ120 | 150-200kg/h | 3200mm | ZB-M-100CC | ZB-2MR-195 |

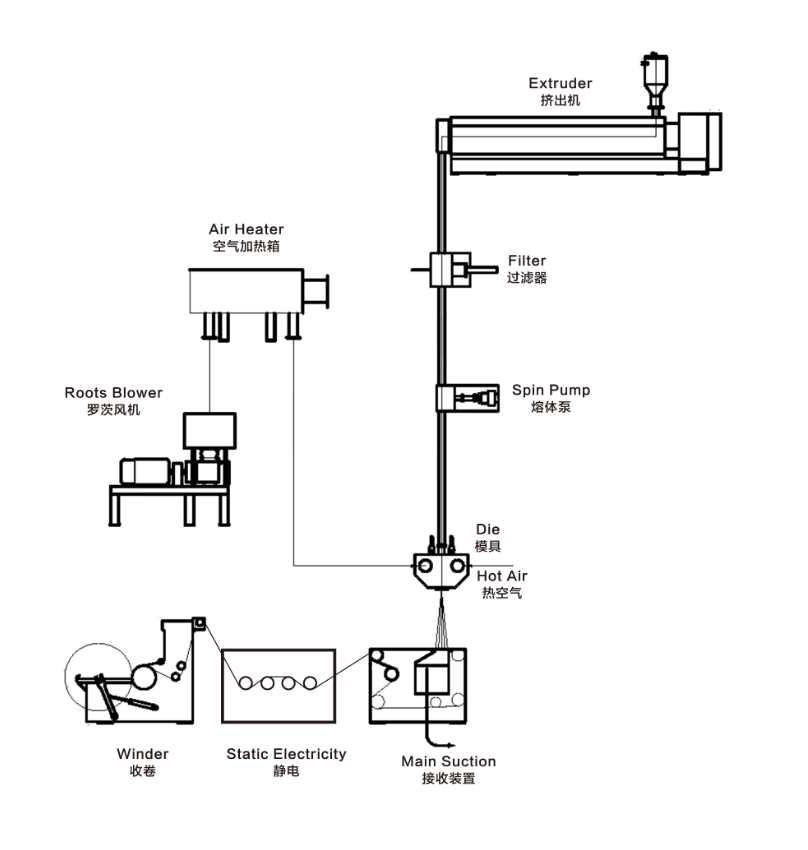

Process flow chart of extruder machine melt blown cloth production line

We can provide feeder system - metering pump - filter(screen changer)

Additives (scrap recovery) ---- raw materials - > melt extrusion - > filtration - > metering - > spinning - > cooling - > drawing - > Netting - > hot rolling - > winding - > slitting - > finished products

| Product model | BT-FNB1600SS | BT-FNB2400SS | BT-FNB3200SS |

| Effective width | 1600mm | 2400mm | 3200mm |

| Weight range | 10-150g/m² | 10-150g/m² | 10-150g/m² |

| Production capacity: | 6-10t | 10-15t | 12-20t |

| Equipment speed | <=350m/min | <=350m/min | <=350m/min |

| Installed capacity | ≈400KVA | ≈500KVA | ≈800KVA |

| Product model | 35m*12m*12m | 35m*15m*12m | 35m*17m*12m |