Melt Pump

- Polymer extrusion melt gear pump

- melt pump for plastic extrusion

- Polymer Reaction Kettle pump

- gear pump rubber extruder

- melt pumps for extrusion

- Melt Gear Pumps for BOPP Films

- ZB-G bearing external melt pump

- melt pump for pvc extrusion

- ZB double shaft drive melt pump

- Explanation of terms for melt pump d

- ZB-X Series chemical gear melt pump

- PID Control System for extrusion

- PLC Control System for extruder

- ZB-U series melt extrusion spinning

- ZB-E series transfer melt pump for e

- ZB-H series high temperature and hig

- ZB-R series gear melt pump for rubbe

- ZB-K series chemical stainless steel

- ZB-D series pipeline melt pump for p

- ZB-F series melt pump for reaction k

- ZB-B series dosing standard thermopl

- ZB-C series plastic granule machine

Screen Changer

- polymer melt filtration screen changer

- recycled plastic screen changer

- slide plate screen changer

- pillar screen changer

- dual bolt screen changer

- continuous screen changer

- screen changer polymer filter

- Plastic extruder filter extrusion sc

- Biodegradable plastic PBAT/PLA hydra

- Single plate hydraulic screen change

- plastic extrusion screen changer

- single plate hydraulic quick screen

- Manual control screen changer

- Double plate continuous hydraulic sc

- Automatic mesh belt continuous scree

- Double piston four screen cavities c

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Dual Bolt double screen cavities hyd

Feeding System

- force feeder extruder

- loss in weight feeder for masterbatc

- continuous feeding system

- Liquid loss in weight feeder

- china volumetric screw doser feeder

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

melt blown progress

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: sale@meltpump.com

- whatsapp: +86 158 38331071

- Tel: +86-371-67991755 / 67992755

- FAX:+86-371-67993277

- Address:No.11 Changchun Road, High-tech Zone, Zhengzhou, China.

News

- Single-Column Dual-Station Hydraulic

- Differences Between Reactor Melt Dis

- BATTE cordially invites you to visit

- single-plate hydraulic screen change

- BATTE Melt Pumps Replace MAAG Pumps

- Application of Melt Pumps in Sheet E

- Melt Pump for PP Filament Production

- Melt Gear Pump Selection 3D Matrix:

- Melt pumps and screen changers are u

- Accessories for melt pumps

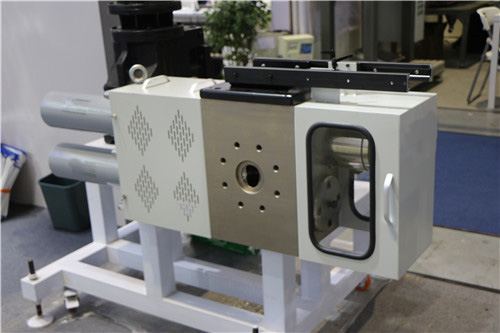

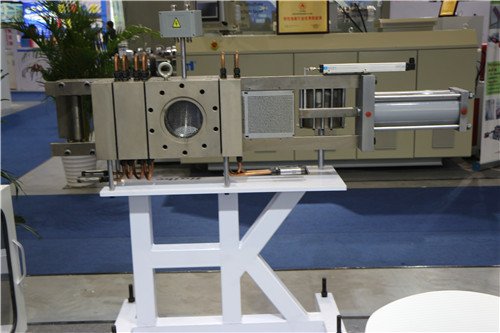

plastic extrusion screen changer

Name: plastic extrusion screen changer

Category: hydraulic screen changer for plastic extrusion

Introduction:batte offering hydraulic screen changer, continuous operation extrusion screen changer without machine halt or disruption of melt flow....

Manufacturer: BATTE Machinery China

sale@meltpump.com

continuous operation extrusion screen changer

Benefits of this continuous plastic extrusion screen changer

Increased production

Reduced downtime & scrap

Leak-free operation

Increased filtration area

Reduced inlet pressures

Accurate, repeatable screen changes

Reduced maintenance

Zhengzhou BATTE chinaplas

continuous plastic extrusion screen changer Technical data

1)The main body of the screen changer

Raw material:alloy steel(38CrMoAlA)

Surface treatment:Nitriding treatment

Depth of Nitrated Layer: 0.40-0.70mm

Nitrided hardness:950-1050Hv

Fragility of nitration: Less than grade 1

Flow channel treatment: chrome plated

Depth of chromium-plating:0.05-0.1mm

Hardness of surface after chromium-plating:HV950HV

2)Drive system:Hydraulic unit:

3)Control system

Electrical controlling system: warnning device,pressure and temperature transducer, are included

Get more informations and price list !!!

Zhengzhou BATTE melt pump factory

continuous plastic extrusion screen changer Features

Two round removable breaker plates on each bearing piston

"Continuous type" means operation of screen change without machine halt or disruption of melt flow.

Fit for almost all kinds of polymer

It works well under the high pressure 400bar(40Mpa) not impact the high performance.

The filtration screen area covers from 56cm² to 520cm², d

epending on the size, fit for output range from 30kg/h to 1

800kg/h.

Parameters of continuous plastic extrusion screen changer:

| Type | Capacity (kg/h) | Dimension (mm) | Screen size | Heater | |||||||

| L1 | L2 | L3 | L4 | Diameter (mm) | Area (cm2) | Quantity | Voltage (v) | Power (w) | |||

| ZB-DSP-80 | 110-300 | 140 | 775 | 220 | 330 | 80 | 50*2 | 6 | 230/400 | 1200/1700 | |

| ZB-DSP-100 | 180-500 | 170 | 895 | 250 | 400 | 100 | 78*2 | 6 | 230/400 | 1600/2000 | |

| ZB-DSP-120 | 350-800 | 200 | 1005 | 310 | 470 | 120 | 113*2 | 6 | 230/400 | 200/2400 | |

| ZB-DSP-150 | 450-1200 | 245 | 1170 | 350 | 560 | 150 | 176*2 | 6 | 230/400 | 2400/3000 | |

| ZB-DSP-180 | 500-1500 | 290 | 1335 | 440 | 600 | 180 | 254*2 | 6 | 230/400 | 4000/4800 | |

| ZB-DSP-200 | 800-2500 | 320 | 1455 | 450 | 670 | 200 | 314*2 | 8 | 230/400 | 4500/5300 | |

| ZB-DSP-250 | 1400-3700 | 395 | 1760 | 490 | 760 | 250 | 490*2 | 8 | 230/400 | 5000/6000 | |

Notes: The capacity will be affected by the fluidity, filter fineness and purity of materials.

Get more informations and price list !!!

Next:Single plate hydraulic screen changer with four working station