Melt Pump

- Polymer extrusion melt gear pump

- melt pump for plastic extrusion

- Polymer Reaction Kettle pump

- gear pump rubber extruder

- melt pumps for extrusion

- Melt Gear Pumps for BOPP Films

- ZB-G bearing external melt pump

- melt pump for pvc extrusion

- ZB double shaft drive melt pump

- Explanation of terms for melt pump d

- ZB-X Series chemical gear melt pump

- PID Control System for extrusion

- PLC Control System for extruder

- ZB-U series melt extrusion spinning

- ZB-E series transfer melt pump for e

- ZB-H series high temperature and hig

- ZB-R series gear melt pump for rubbe

- ZB-K series chemical stainless steel

- ZB-D series pipeline melt pump for p

- ZB-F series melt pump for reaction k

- ZB-B series dosing standard thermopl

- ZB-C series plastic granule machine

Screen Changer

- polymer melt filtration screen changer

- recycled plastic screen changer

- slide plate screen changer

- pillar screen changer

- dual bolt screen changer

- continuous screen changer

- screen changer polymer filter

- Plastic extruder filter extrusion sc

- Biodegradable plastic PBAT/PLA hydra

- Single plate hydraulic screen change

- plastic extrusion screen changer

- single plate hydraulic quick screen

- Manual control screen changer

- Double plate continuous hydraulic sc

- Automatic mesh belt continuous scree

- Double piston four screen cavities c

- Single plate double screen cavities

- Single piston double screen cavities

- Double piston four screen cavities b

- Dual Bolt double screen cavities hyd

Feeding System

- force feeder extruder

- loss in weight feeder for masterbatc

- continuous feeding system

- Liquid loss in weight feeder

- china volumetric screw doser feeder

- Multi-component loss in weight feede

- Micro loss in weight metering feeder

- Single screw gravimetric dosing feed

- Twin screw loss in weight metering f

melt blown progress

contact us

- Batte Machinery Zhengzhou Co., Ltd.

- E-mail: sale@meltpump.com

- whatsapp: +86 158 38331071

- Tel: +86-371-67991755 / 67992755

- FAX:+86-371-67993277

- Address:No.11 Changchun Road, High-tech Zone, Zhengzhou, China.

News

- Introduction to the Basic Structure

- Analysis of the Structure and Functi

- Application, Structure, and Technica

- Melt Pump: The Secret Weapon on the

- What are the roles of the metering p

- Structure, Performance, and Applicat

- dual-column screen changer in the me

- Screen Changer Selection Strategy Ba

- Relationship Between Melt Pumps and

- Application scope of mesh belt autom

Foamed products XPS EPE

-

Melt pumps and screen changers for foam production lines

XPS insulation board, PET foam, KT board, EPE pearl cotton special melt pump, also known as melt metering pump, for a variety of plastic, rubber, elastomer and

learn more >>

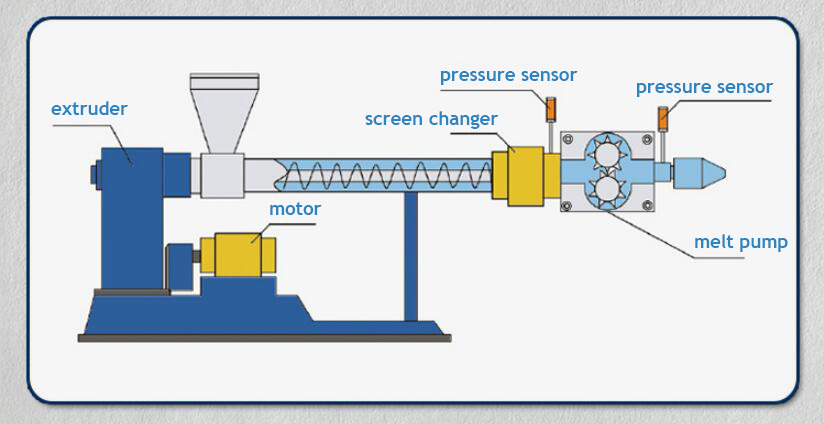

Your Extruder's Best Friend-extrusion melt pump function

The simplest ways to make the best of extrusion melt pump function installing into extruders, Melt pumps is known as an accurate metering device that build pressure more effectively than a screw and provide more consistent pressure and volume of output than a screw, eliminates surging of the extruder screw. The extruder fills the gears from the suction side and the rotating gears discharge the polymer on the other side. it is to keep the flow and pressure of the plastic melt flow to the die at a continuous and constant level, reduces back pressure and increases output of the complete line (up to 20%). The quality of the extruded material is thus highly increased. It is used in a wide range of applications from PET sheet and rubber extrusion to recycling and compounding.

1, improve the quality of the final products

2,greatly improve the plasticizing of the raw material

3, make the product structure more homogeneous and product surface smoothness

4, protect the down stream equipments, such as Batte melt pumps and the extrusion dies

1, to improve the stability of the product size

2,melting quality control

3, increase output

4, reduce the raw materil consumption

5, improve the flexible of the extruder

6, protect the extrusion die ,extend the service life of the extruder

1, improve the melt plasticaction

2, improve the quality of the products

3, extend the service life of the extruder

4, greatly increase the output of the products

5, reduce the labor interference

6, reduce the unqualified products

-

Three layer extrusion sheet melt gear pump

-

melt pump for plastic hdpe sheet extrusion

-

batte extrusion metering polymer melt pumps

-

ZB-F series melt pump for reaction kettle

What do we need to pay attention when using the screen changer nad melt pump?

1, we should operate the screen changer and melt gear pump as the safety manual, prevent an electrical shock

2, To prevent ourself scald

3, do not disassemble the screen changer and the melt gear pump, any questions, please contact with the supplier.

Thermoplastic transportation/metering, conveying polymer melt

| Scope of Field | Examples |

| Polymer Melt | film, pipe, plate, sheet, granulation |

| High Temperature or High Viscosity Materials | PC, PMMA, ABS, HIPS, PET, PVB, PS, PP, PA, PE, PVA etc. |

| Chemical Fiber Melt | polyester for cotton-fiber, polypropylene |

| Other Polymer Melt Materials | rubber, asphalt, paint, adhesives, coatings, lubricants |